Learn about composites fabrication, assembly, repair; CNC machining; and composite manufacturing. Composites students are prepared for entry-level positions in industries including aviation, marine, recreation, green energy, and manufacturing.

Composites Technology — NSC STEM Pathways

$25

- Description

- What students will learn

- Learning objectives by module

- Course assessments, activities, and outline

- Other course details

- System requirements

- Included instructor tools

Description

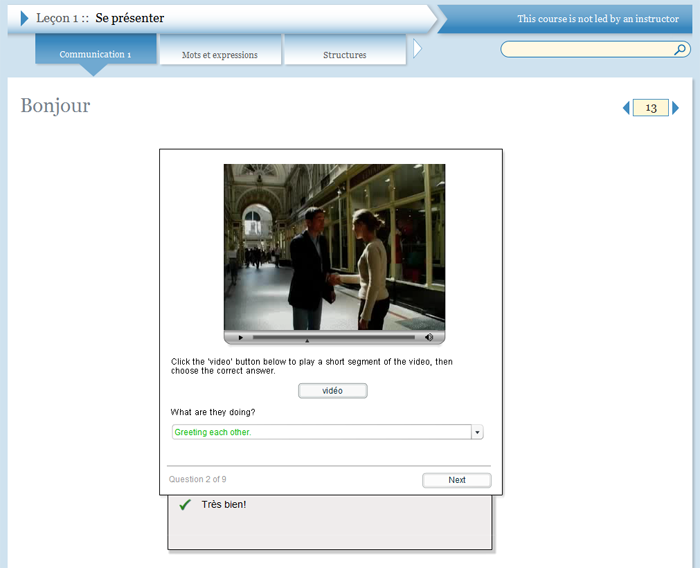

The National STEM Consortium’s (NSC) Composites Technology Pathway is a one-year, 30-credit hybrid course (mixture of online and face-to-face) consisting of 16 mini-courses. The entire Pathway consists of a set of materials a school or institution can customize for their program’s or students’ needs. Each mini-course includes:

- A downloadable Teaching Toolkit with the following documents:

- A course introduction (READ ME) that explains the course, including course structure, learning outcomes, prerequisites, and suggested texts.

- A suggested syllabus that you can customize to your college, department, course, and individual preferences.

- Suggested lesson plans with learning outcomes and assessments, lesson outline, teaching tips, and instructional resources.

- Supplemental materials as labeled.

- OLI online modules to help prepare students for face-to-face instruction, by providing mini-lessons and interactive drills that address common sticking points

NOT INCLUDED are the recommended textbooks. See the README First document in the Teaching Toolkit for each mini-course for a list of recommended texts.

Created through a collaboration with the OPEN Platform+ program, the National STEM Consortium academic certificate in Composites Technology is built on a 30-semester-credit model and includes two tracks: (1) Composites Fabrication, Assembly, and Repair, and (2) CNC Machining and Composite Manufacturing. Graduates are prepared for entry-level positions in industries including aviation, marine, recreation, green energy, and manufacturing.

NSC STEM Pathways

STEM Pathways are five certificate programs developed by the National STEM Consortium (NSC). NSC is a collaborative of ten colleges in nine states, funded by a U.S. Department of Labor grant to develop one-year, 30-credit certificate programs in five Science, Technology, Engineering, and Mathematics (STEM) fields: Composites Technology, Cyber Technology, Electric Vehicle Technology, Environmental Technology, and Mechatronics Technology. In collaboration with the OPENPlatform+ program, these have been implemented and made available on the OLI platform, with learning activities targeting specific areas of challenge, resources to support instructors and implementation guides for administrators.

The STEM Pathways use an innovative two-part STEM Bridge program to improve completion and success rates of students. This program embeds contextualized refresher instruction in mathematics, communication, and professionalism to eliminate traditional remedial courses and prepare students for success in demanding technical courses. The NSC STEM Readiness course enables students who are not fully college-ready in math to enroll and succeed in the technical curriculum, thus broadening the pool of potential students and opening STEM careers to a greater number of workers. The second element of the STEM Bridge is designed as a FAST TRACK program to support learners who require more intensive, up-front development of the basic skills required for access to the technically demanding educational pathways into STEM occupation. The STEM Foundations course provides elements of this FAST TRACK approach.

The NSC academic model is built on four research-based strategies that, when combined, yielded an average 69% on-time completion rate across its students nationwide.

First, NSC instruction is outcomes-driven, delivering learning outcomes mapped to industry standards. NSC member colleges formed regional advisory boards to respond to industry needs and employer requests. These materials include implementation guides with examples and recommendations from colleges whose regional economies support a diversity of industries, such as healthcare, construction, and the military.

Second, NSC programs are one-year, 30-semester-credit academic certificates. Certificates are a highly effective tool for workforce development, and are most effective when they are long enough to be rigorous yet short enough to be achievable. The certificate-level credential is a missing, but critical, on-ramp to career pathways for adult learners who often lack access to and awareness of high-demand careers in STEM fields. Graduates receive the greatest return on investment from certificates of one year or longer with a load of thirty-six semester credits or fewer.

Third, NSC programs use a built-for-completion structure including a program navigator, cohort structure, block scheduling, compressed timeline, enhanced student support services, and employer partnerships. Research has shown that it is the combination of strategies, rather than any single strategy, that boosts student success. Specifically, a growing body of evidence argues for “strategy intervention at a more comprehensive and integrated level that aims at simultaneous change focusing around whole program design and delivery – improving the coherency of instruction and educationally relevant services that students need as they move through their program of study.”

Last, NSC programs embed contextualized refresher instruction in mathematics, communication, and professionalism to eliminate traditional remedial courses and prepare students for success in demanding technical courses. The NSC STEM Readiness course enables students who are not fully college-ready in math to enroll and succeed in the technical curriculum, thus broadening the pool of potential students and opening STEM careers to a greater number of workers.

Colleges aiming for systemic change in their student completion and achievement levels are strongly advised to adopt the entire NSC academic model. However, NSC programs are flexible by design, allowing institutions to customize implementation to their regional economy and local conditions. For example, a college might choose to pursue implementation in stages.

STEM Pathway Programs

- Composites Technology

- Cyber Technology

- Electric Vehicle Technology

- Environmental Technology

- Mechatronics Technology

STEM Bridge Courses

What students will learn

The NSC Composites Technology certificate program has learning outcomes in the categories of Critical Thinking and Problem Solving; Materials, Techniques, and Processes; Professionalism; Safety; Technical Documentation; and Tools and Equipment. These outcomes are broad themes of the program, achieved in one or more of its courses:

- Apply mathematics and physics to solve industrial/manufacturing problems.

- Assemble what is learned and apply in novel circumstances to solve problems, developing and using critical thinking.

- Demonstrate knowledge and mastery of techniques of industrial composites fabrication, assembly, and repair, including uses of tooling.

- Appropriately select materials and processes for specific applications.

- Demonstrate knowledge and understanding of the uses, strengths, limitations, and other characteristics of metals, alloys, non-metals, and composite materials.

- Attach fasteners, metal components, brackets, and fittings to composite and/or metal materials with precision and proper care.

- Implement appropriate techniques to inspect structures.

- Select and implement appropriate repair techniques.

- Follow protocols created in support of LEAN practices.

- Demonstrate professional behavior by working with a team and following standard operating procedures (SOPs).

- Develop and prepare to execute a career plan.

- Seek clarification from colleagues, supervisors, and customers in an appropriate manner.

- Adhere to safety requirements relating to personal, consumer, environmental, regulating agency, and employer concerns.

- Execute and understand documentation of work/project orders, material use, equipment, and tooling.

- Read and interpret drawings and prints typical in manufacturing, fabrication, assembly, and repair environments.

- Properly identify and safely operate tools and equipment to industry standards.

- Set up and operate machine tools including, but not limited, to manual machines, CNC machines, and injection molding stations.

- Correctly inspect finished and unfinished machined parts.

- Set up machine speeds and feeds properly.

Learning objectives by module

Pathway 1: Composites Technology

- Advanced Composites Fabrication and Assembly

- Define glass transition temperature and describe what effect this has on a matrix.

- Define ply orientation including warp clocks, ply lay-up tables, symmetry, balance, quasi-isotropy, and nesting/stacking.

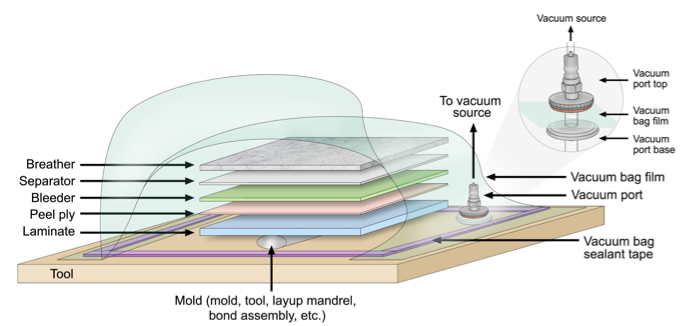

- Describe and demonstrate vacuum bagging including knowledge of atmospheric pressure and requirements for successful vacuum bagging.

- Describe and differentiate between the different fiber terminology (i.e. filament, strand, tow, yarn, etc.) as well as the different woven/non-woven and multi-axial fabrics.

- Describe how Vacuum Infusion Processes depend on Darcy’s Law.

- Describe the different cure cycles, including legacy cure and two-step profile.

- Identify the different types of matrices and be able to compare and contrast between thermoset and thermoplastic matrices.

- Applied Math

- Read a depth micrometer.

- Read an English outside micrometer.

- Applied Physics

- Solve for weight, mass, and gravity using the given formulas and using appropriate units.

- Use gas laws and their formulas to solve for pressure, temperature, and volume.

- CNC Machining

- Calculate the correct feed rate for milling machine cutting tools.

- Calculate the correct RPM rate for milling machine cutting tools.

- Drawings and Prints

- Calculate taper per inch and taper per foot on blueprints and drawings.

- Interpret dimensional codes of external screw threads.

- Injection Molding

- Identify the basic components of a standard injection mold.

- Identify the different types of matrices and be able to compare and contrast between thermoset and thermoplastic matrices.

- Introduction to Composites

- Define ply orientation including warp clocks, ply lay-up tables, symmetry, balance, quasi-isotropy, and nesting/stacking.

- Describe and demonstrate vacuum bagging including knowledge of atmospheric pressure and requirements for successful vacuum bagging.

- Describe and differentiate between the different fiber terminology (i.e. filament, strand, tow, yarn, etc.) as well as the different woven/non-woven and multi-axial fabrics.

- Identify the different types of matrices and be able to compare and contrast between thermoset and thermoplastic matrices.

- Machine Tool Theory

- Interpret dimensional codes of external screw threads.

- Semi Precision and Precision Measurement

- Read a depth micrometer.

- Read an English outside micrometer.

Course assessments, activities, and outline

PATHWAY 1: Composites Technology

Course 1: Applied Math

Course 2: Semi Precision and Precision Measurement

Course 3: Drawings and Prints

Course 4: Professionalism

Course 5: Safety

Course 6: Applied Physics

Course 7: Materials and Processes

Course 8: Introduction to Composites

Course 9: Composites Lab Tech A

Course 10: Advanced Composites Fabrication and Assembly

Course 11: Advanced Composites Repair

Course 12: Composites Lab Tech B

Course 13: Machine Tool Theory

Course 14: Machine Operations Lab

Course 15: CNC Machining

Course 16: Injection Molding

Other course details

System requirements

OLI system requirements, regardless of course:

- internet access

- an operating system that supports the latest browser update

- the latest browser update (Chrome recommended; Firefox, Safari supported; Edge and Internet Explorer are supported but not recommended)

- pop-ups enabled

- cookies enabled

Some courses include exercises with exceptions to these requirements, such as technology that cannot be used on mobile devices.

This course’s system requirements:

- none listed (subject to change)

Included instructor tools

Instructors who teach with OLI courses benefit from a suite of free tools, technologies, and pedagogical approaches. Together they equip teachers with insights into real-time student learning states; they provide more effective instruction in less time; and they’ve been proven to boost student success.